|

||||||||||||||||

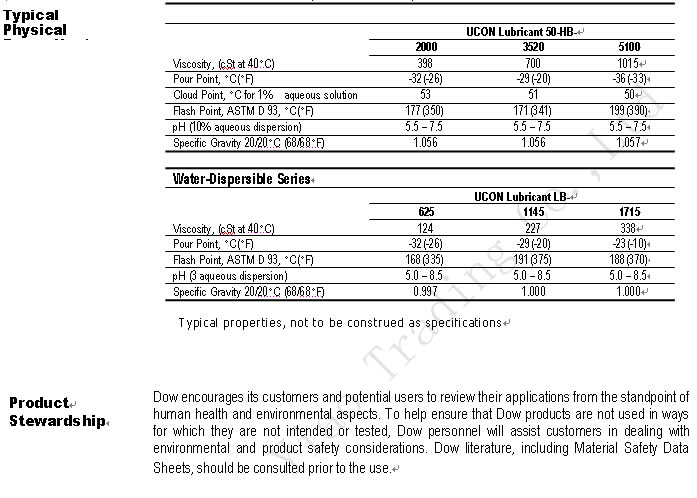

UCON Lubricant 50-HB-5100

Product The chemical nature of UCON Antifoam gives them a physical property known as inverse solubility. This means that an increase in the temperature of an aqueous system in which UCON Antifoams are present causes a decrease in solubility of the UCON Antifoam beingused. At or above the cloud point (the initial effective temperature), the UCON Antifoam separates from solution and acts as an extremely effective defoamer. Reduction of the system temperature below the cloud point enables the UCON Antifoam to again become solubilized. This cycling may be indefinitely repeated without degradation of the product, as long as the system temperature does not exceed 150∼C.

Dosage Levels and Most Often Used 每 UCON Lubricant 50-HB-5100 UCON Lubricant LB-625 is employed in certain submerged culture fermentation processes at concentrations of 50 to 5000 ppm. This antifoam is specifically of value in fermentation employing actinomyceteles-type organisms, and is used to produce a wide range of antibiotics, including tetracycline and rifamycin B complex. It is also widely used in the production of steroids. UCON Lubricant LB-625 is sterilizable and stable over a wide range of fermentation processing conditions. Most Often Used 每 UCON Lubricant LB-625 Acid Gas Removal Units (for systems purifying natural gas with ethanol amines) 每concentrations vary from 30 ppm to over 200 ppm, but most systems can be started on 100 ppm. Results are rapidly observed, and optimization is, therefore, simple.These products often replace natural oils like oleyl alcohol, which may become rancid. Note: Concentration must be based on total volumes of ethanolamine and water in the system, with makeup and blowdown of each included. Most Often Used 每 UCON Lubricant LB-1715 Sea Water Desalination 每 concentrations in the total system from 0.07 up to 0.20 ppm have been encountered, but most multistage flash (MSF) evaporator systems use 0.07 to 0.10 pm. This is equivalent to about 1.2 kg per day of UCON Antifoam per one million imperial gallons per day (MGD) of distillate being produced, or 6 kg per day for each 5 MGD evaporator. Introduction is often done by continuous injection of a concentrate, made by dispersing the UCON Antifoam with water (and also the antiscale products, if desired), directly into the make-up stream. It is important to maintain thorough mixing while dosing. Most Often Used 每 UCON Lubricant LB-1145

|

||||||||||||||||